Subsea Services

At gatewayogs, our Subsea Services are designed to address the complex challenges of underwater operations with precision, reliability, and safety. With a proven track record in delivering exceptional subsea solutions, we empower industries like oil and gas, renewable energy, and marine construction to operate efficiently and effectively in the most demanding environments.

"Our subsea services are IMCO certified, ensuring world-class safety and environmental compliance. This certification underscores our commitment to delivering reliable and responsible subsea solutions."

Our Expertise

- Subsea Installation and Commissioning We ensure seamless deployment of underwater infrastructure, from pipelines and cables to subsea equipment, adhering to the highest industry standards.

- Inspection, Maintenance, and Repair (IMR) Our advanced ROV (Remotely Operated Vehicle) and diver-assisted services provide detailed inspections, efficient maintenance, and effective repairs to extend the life of your assets.

- Pipeline and Cable Laying Leveraging state-of-the-art technology, we execute precise and reliable installation of subsea pipelines and cables, ensuring uninterrupted performance.

- Dredging and Excavation From seabed preparation to removal of debris, our subsea dredging and excavation services are tailored to meet project-specific requirements.

- Decommissioning Services Safely and efficiently retiring subsea assets, we offer comprehensive decommissioning solutions to minimize environmental impact.

Why Choose us

- Advanced Technology: Equipped with cutting-edge ROVs, autonomous underwater vehicles (AUVs), and specialized tools for superior performance.

- Expert Team: Our skilled professionals have years of experience in subsea engineering and operations.

- Commitment to Safety: Stringent safety protocols ensure the well-being of our team, your assets, and the environment.

- Tailored Solutions: We adapt our approach to your unique project needs, ensuring cost-effective and timely results.

Industries We Serve

- Oil and Gas

- Renewable Energy

- Marine Construction

- Defense and Research

Hottaping / Corrosion Monitoring

We specialize in Hot Tapping and Corrosion Monitoring solutions to ensure the integrity, safety, and efficiency of your pipeline and facility operations. Our advanced techniques and industry expertise empower you to maintain seamless operations without costly disruptions or safety risks.

Hot Tapping Services

Hot tapping is a critical technique for modifying pipelines, tanks, or pressure vessels without shutting down operations. Whether you need to install a branch connection, conduct repairs, or perform system maintenance, our hot tapping services deliver reliable and safe solutions for your needs.

Our Hot Tapping Capabilities

- Pipeline Modifications: Adding connections, rerouting, or isolating sections of a pipeline.

- Pressure Vessel Access: Safely installing taps in pressurized systems.

- Emergency Repairs: Immediate access for repair without operational downtime.

- Custom Solutions: Tailored hot tap designs for unique project requirements.

Benefits of Our Hot Tapping

- Maintain uninterrupted operations.

- Eliminate the need for costly shutdowns.

- Ensure maximum safety with advanced tools and skilled personnel.

Corrosion Monitoring Services

Corrosion is a major threat to asset integrity in industrial environments. Our corrosion monitoring solutions provide proactive insights into the condition of your systems, helping you make informed decisions to extend asset life and prevent failures.

Our Corrosion Monitoring Solutions

- Online and Real-Time Monitoring: Continuous tracking of corrosion rates with advanced sensors.

- Non-Invasive Inspections: Safeguard your assets without disturbing operations.

- Customized Corrosion Control Plans: Tailored strategies to mitigate risk and optimize maintenance.

- Data Analysis and Reporting: Comprehensive reports to support informed decision-making.

Why Choose Our Corrosion Monitoring

- Prevent costly asset failures with early detection.

- Reduce maintenance costs through proactive measures.

- Ensure compliance with industry standards and regulations.

MTM (AQUA MTM)

We are proud to offer Magnetic Tomography Method (MTM) services, a cutting-edge, non-invasive technology for pipeline integrity assessment. MTM is a revolutionary diagnostic tool that identifies stress concentration zones (SCZs) and potential defects in pipelines without the need for excavation or operational shutdowns.

Read moreWhat is Magnetic Tomography Method?

MTM is a passive magnetic inspection technique that analyzes the natural magnetic field of pipelines. By detecting variations in the magnetic field, MTM identifies stress, corrosion, mechanical damage, or other anomalies that may compromise pipeline integrity.

This advanced method is ideal for assessing buried, submerged, or inaccessible pipelines, making it an invaluable tool for industries reliant on critical pipeline infrastructure.

Key Features of MTM

- Non-Invasive: No need for direct contact with the pipeline, excavation, or intrusive inspections.

- Real-Time Data: Immediate identification of stress zones and anomalies.

- Operational Efficiency: No interruption to pipeline operations during the inspection.

- Comprehensive Coverage: Suitable for pipelines in various environments, including subsea, buried, and aerial pipelines.

MTM Service Applications

- Pipeline Integrity Assessment: Detect stress concentration zones and mechanical damage.

- Corrosion Monitoring: Identify areas prone to corrosion or wall thinning.

- Post-Event Evaluation: Analyze pipelines after natural disasters or mechanical impacts.

- Preventive Maintenance: Proactively address potential risks before failures occur.

Benefits of Using MTM

- Cost-Effective: Reduce inspection costs by eliminating the need for excavation or shutdowns.

- Enhanced Safety: Early detection of stress or defects minimizes the risk of pipeline failures.

- Environmentally Friendly: Non-invasive technology reduces the environmental footprint of inspections.

- Versatile: Applicable to pipelines in oil and gas, water, and chemical industries.

Tank Inspection

At Gateway Ventures, in collaboration with Planys, we leverage advanced marine robotics, cutting-edge sensors, and AI-powered digital reporting to revolutionize inspection processes. Our solutions integrate fundamental science with modern technology and digitalization to enhance shutdown efficiency and optimize asset performance.

Our Tank Inspection Services

-

Visual Inspection:

- Assess tank walls, roofs, and foundations for visible signs of damage or corrosion.

- Identify cracks, leaks, or deformations.

-

Non-Destructive Testing (NDT):

- Ultrasonic Testing (UT) to measure wall thickness and detect corrosion.

- Magnetic Particle Testing (MPT) for surface crack detection.

- Dye Penetrant Testing (DPT) for identifying leaks and fractures.

-

Internal Inspections:

- Detailed evaluation of internal surfaces to detect corrosion, pitting, and other issues.

- Robotic inspection options for confined or hazardous spaces.

-

Leak Detection and Integrity Testing:

- Hydrostatic testing to evaluate the structural integrity of tanks.

- Vacuum box testing for identifying small leaks.

-

API Standard Compliance:

- Inspections conducted per API 653 and API 650 standards for above-ground storage tanks.

-

Corrosion Monitoring and Prevention:

- Comprehensive corrosion assessments and customized solutions to mitigate future risks.

Our Case Studies

Online Inspection of Storage Tank

ROV was deployed to inspect the tank in online conditions (without de-watering) to pro-actively plan for the upcoming shutdown

Defects identified were categorised by severity (moderate/minor) & along with UT measurements were geo-tagged on the tank drawing visible through the Planys Analytics Dashboard (PAD).

Online Inspection of Sump / Basin

Since commissioning, inspection was not performed due to lack of shutdown (pumps running 24x7). Unmanned ROV inspection was preferred due to confined region, safer option & limited operational window. 25+ defects were identified along with construction debris that could choke the pumps

Underwater NDT of Jetty Piles

Jetty piles had corrosion protection insulation and it was not desired to remove the same for corrosion mapping.

Planys deployed a sophisticated underwater NDT method to assess corrosion in the piles without exposing the bare surface thus eliminating the need for cleaning of marine growth.

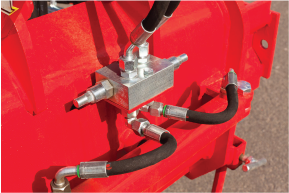

Hydraulics & Instrumentation

Hydraulic systems are one of the most crucial elements associated with the oil and gas industry. We have an individual reputation in market for offering exceptional, durable, and highly feasible hydraulic systems and instrumentations.

Read moreOur team of industry professionals will work with you to isolate the problem and deliver the right solution for your needs. We also have a team of qualified hydraulic specialists who can visit your site and assist with the installation and start-up of your new system and perform repairs in the field.

Experienced repair technicians can test and calibrate hydraulic pumps, gauges, dead weight testers, pressure comparators or any equipment for that matter.

HOSE CRIMPING & TESTING

- Hose crimping , testing and certification.

- Custom made hoses as per client requirements.

- Total solution for the hoses and fittings.

TEST BENCH

- Overhaul and testing of hydraulic pumps, motors, cylinder and valves.

- Designed around a multi station hydraulic test center.

- Testing as per manufacturer’s specification.

TESTING & CALIBRATION

- Calibration of Gauges, Dead weight testers and pressure comparators.

- Calibration of temperature, torque, electrical and dimensional equipment.

- Technical support from well experienced service personnel.

Welding Services

Welding is an important process in upstream, midstream, and downstream sectors of the oil and gas industry like in any other process industry. we offer our customers the largest and most comprehensive product portfolio of cutting and welding equipments.

Read moreWhether destined for use in challenging scenarios or in standard applications, our high quality equipments are ideally suited for all applications in the Oil and Gas industry.

Gateway OGS offers a vast range of top quality equipment that can dextrously handle all the welding requirements of the oil and gas industry.

- Manual Metal Arc (MMA) Equipment

- Manual Inert/Active Gas (MIG/MAG) Equipment

- Tungsten Inert Gas ( TIG) Equipment

- Plasma Cutting & Welding Equipments

- Gas cutting apparatus- flow meters, specialty gas regulators

- Welding Generators

- Gas cutting apparatus

- MIG /TIG Torches

- Power Generators

- Electrode holding & rebacking ovens

Pneumatics Services

When when it comes to pneumatics for the oil and gas industry, we’ve got you covered. Our experienced pneumatic technicians repair and fix any air system, whether we designed it or not.

Read moreIf your current equipment requires spare parts or upgraded control systems, we’ve got you covered there too. We provide you with quality products and services which meet your exacting needs in terms of reliability, safety and short lead-times.

We can always put your industry-specific requirements first and provide you with the optimal solution and service We always make sure that we deliver our promise of pristine service beyond your expectation.

- Air Systems Evaluation, Selection & Design

- Fixing & Repairing

- Installation, Commissioning & Start-up

- On Call Visit Agreement

- Preventive Maintenance Program

- Overhauling Compressors

- Supply of recommended Lubricants for Air Compressors

- Spare Parts, Kits & Consumables

- Upgrading Control Systems

Protective Coating

Oil and Gas industry’s infrastructure can be good only if quality protection is provided and maintained. We’ll help you select the right coating system for various oil and gas equipment and pipelines both upstream and downstream to protect it from extremes of weather.

Read moreWe also help you maintain your equipment properly and extend their lifetime. Gateway OGS has installed Chromascan machine in Almaty and Aktau to respond

to the huge demand of Alkyd, Epoxy and Polyurethane paints in Kazakhstan. It lets us stock bases and pigments in order to meet the immediate requirements of our customers without any delay.

Equipment For Rental

Over extensive fleet of industrial rental control systems, pumps, cylinders, test and flushing equipment covers your need for complete oil and gas field services.

Read moreWith years of experience, we can guarantee you reliable, safe, innovative, and cost-effective equipment rental solution for the downstream, midstream, and upstream sectors of oil and gas industry.

Quite a lot of customers see a rental solution to be more magnetic than buying a product. Gateway OGS provides this service and the benefits are reduced capital expenditure, reduced space for storage and maintenance and reduced risk of failure during the operation of older tools.

- Control systems

- Test and flushing systems

- Chemical injection systems

- High pressure mobile pumps

- Sample PVT Cylinders

- Sampling systems

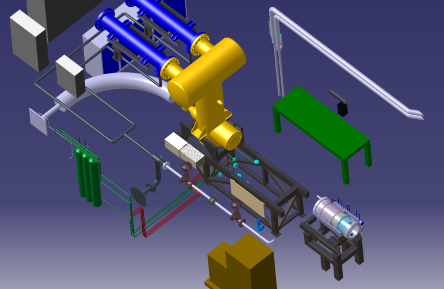

Design & Supply

Gateway OGS’ equipment services comprises of the design and supply of chemical injection systems, high pressure test equipment, hydraulics power units and many other control panels.

Read moreWith accuracy and safety as our guiding principles, our design focuses on providing design efficiency to ensure stringent adherence to milestones, regulations, deadlines, and budget.

We are the preferred choice for organisations from around the world for equipment design with high-quality performance.

We can deliver tailored equipment to suit your application and work with you from design to delivery.

- chemical injection systems

- high pressure test equipment

- hydraulics power units

- well head control panel

- BIO control panel

- Wire line control panel

- Electro/Pneumatic

- hydraulics control system

Our Training

The key to success in any opening in Oil and Gas industry is thorough knowledge of the processes that occur in the various stages starting from Exploration & Production to advanced operations.

Read moreWe provide expert in-house and live field operations oriented training on various subjects including hydraulics and instrumentation installations.

And our training is designed to help your organisation enhance and ensure standards in safety and competency when working in oil and gas fields.

Onsite Services

Gateway’s on-site services division has built an extensive range of precision portable machining equipment and specialist skills. We provide cost-effective workshop-quality machining for the largest and smallest on-site machining projects around the world.

Read moreOur Field Services includes: Filtration, Piping, Oil sampling, Hot oil flushing, Hydro testing and On-site trouble shooting.

Our craftsmen are skilled and will provide you the onsite industrial services you need.

FILTRATION

- Fluid transfer – Electrical operated pump with filters

- Achieve targeted cleanliness levels by offline filtration

- Removal of water, Particles, Oxidation by products and varnish from oil

PIPING

- Providing complete piping solution

- Onsite pipe bending and Installation

- Supply of material and components

OIL SAMPLING

- Onsite particle counting of oil to confirm cleanness level

- Online and offline oil sampling can be carried out by Laser particle counting machine

- The print out result available from the particle counter

HOT OIL FLUSHING

- Quick, economical, effective and safer flushing method

- Achieve manufacturer and client specification

- Using turbulent flow for effective clean up of a system

HYDRO TESTING

- Testing of Tubes, pipes, hoses

- Certification of tubes, pipes, hoses

- Available comprehensive range of high pressure mobile pump test equipment, data loggers and chart recorders

ONSITE TROUBLE SHOOTING

Gateway OGS carry out onsite repairs, diagnosis and troubleshooting of Hydraulic & Pneumatic equipment and components